Knowing the kind of tire your car needs or has, is imperative for you because it can help you understand the details of its functionality properly. There are various types of tire tread designs and each affects the usage of the tire in one way or another.

But before discussing those types, we have to understand the terms associated with it. And this article is going to help you a lot in understanding all of them, which is also going to help you in getting the best tire for your needs.

Table of Contents

Starting with their inner construction:

There are a few terms that you often hear, when it comes to tire construction, so we are going to go through all of them in a nice and a easier understanding way.

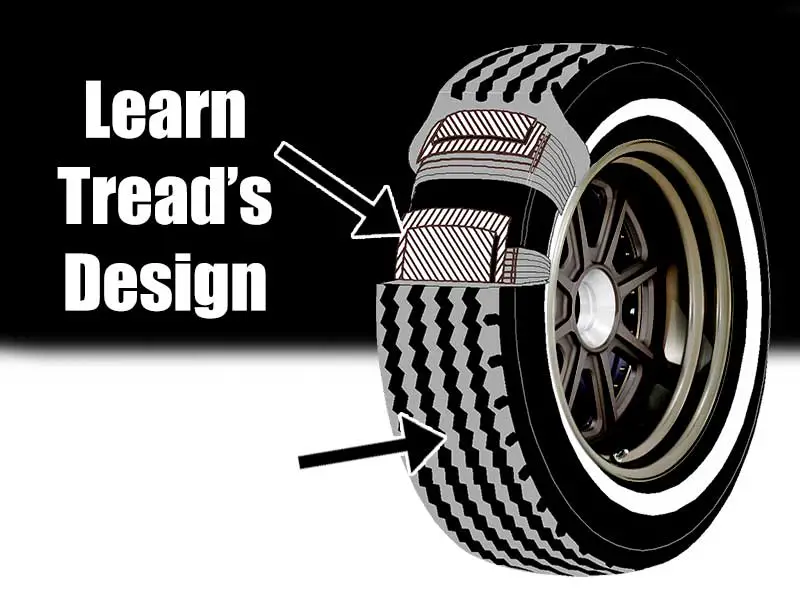

Tire’s Tread:

Tread is simply the outer rubber on the tire you see. The rubber is mostly made out of silica combined with other carbon compounds, to make them either softer or harder.

All tires have different rubber composition, for example summer tires are a little harder, while winter tires are softer, so with freezing temperature they would stiffen up.

But the same softer rubber in summer will remain soft and would wear off/burn out quickly.

Similarly, summer tires are already stiff, so in winter, they stiffen up even more and lose the grip required. That’s why winter tires can’t be used in summer and vice versa.

Tire Sidewalls:

All tires have “Side” “Walls” to them. Most of them are marked with “inner” or “outer” to represent which side has to be shown outwards on a rim.

Usually sidewalls are the weakest when it comes to tire’s construction.

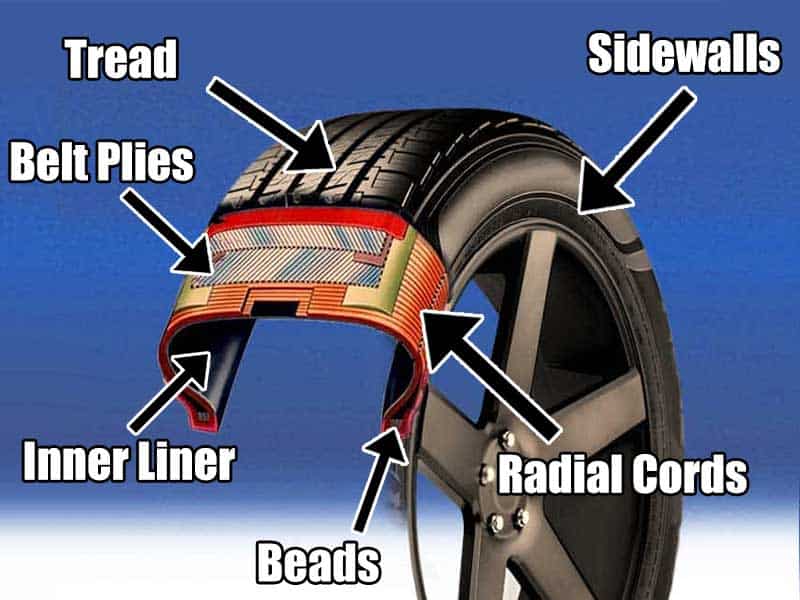

Belt Plies:

These are usually 2 steel belts that cover most of the central tire area underneath.

They are then covered with 1 or 2 layers of nylon belts.

Like in the image above, you can see the two steel belts (of dark and light grey) covered with 2 layers or plys of nylon.

Here you can see the “Belt Plies” labelled in the image above. These are just layers made out of steel (that’s why they are called 2 ply steel. Similarly, there are other layers made out of nylon.

See how these layers or flaps are just stacking in the center, and not on sidewalls.

So this would mean that underneath sidewall, there are fewer layers. That’s why sidewalls are considered the most vulnerable part of the tire (especially when it comes to off road tires which are more prone to get damage there).

Radial Cords:

These sidewalls only have what they call “radial cords” underneath them. They are simply polyester material-made cords which are spirally wound. (Or in other words it makes the skeleton of the tire).

In the diagram you can see these polyester “sheets” have 2 layers.

And so, they are called 2-ply. And the sidewalls here would be called 2-ply sidewalls.

Inner Liner and Beads:

Inner liner is simply coating/layer on the inside of the tire. It’s made out of synthetic rubber which can endure the air pressure in the tire.

The bead is a cable made out of steel that makes the lock with the rim, so there is no leakage of air.

In other words, with beads, the tires are made air tight.

It’s also labeled in the image above.

So to sum up the inner construction:

Most of the tires have inner construction of 2 ply polyester casing, with 2 ply high strength steel belts which is covered with 1 layers of nylon. So you get a 2 ply sidewalls.

This is the most common inner construction of the tire. To make tire stronger, the body plies are wound another time and extra layers of body plies are stacked on top.

In case of 3 ply construction, the radial cords or polyester skeleton on this tire wounds around 3 times.

Part’s of the tire (on the tread):

Tread is a part of the tire that makes contact with the surface of the road. And there are some design terms that you would hear out mostly.

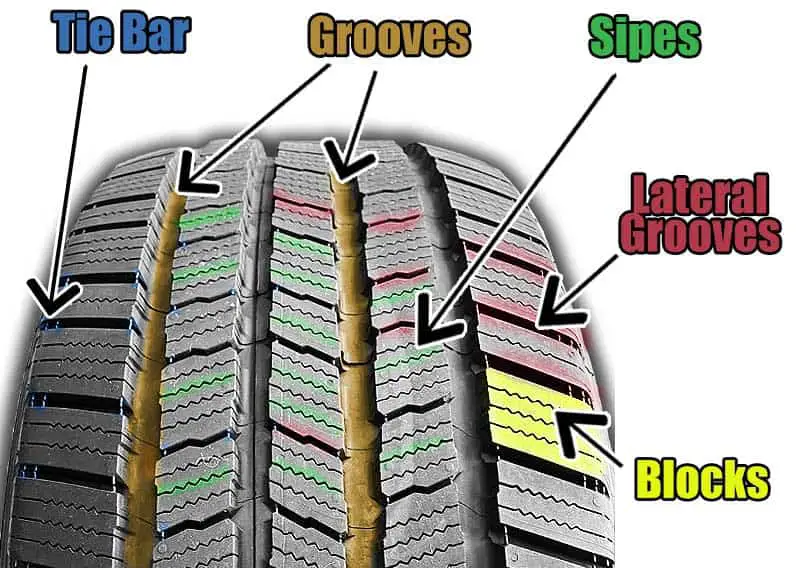

Let’s start with Grooves.

These are the deep spaces that run around the structure of the tire tread. They are further divided in to Lateral grooves which run side ways, and just grooves or longitudinal grooves run circumstantially with the tire.

You can consider them as valleys between. They are colored with orange (for longitudinal grooves) and red (for lateral grooves).

These valleys/grooves are made for water/dirt/mud to pass through on the road.

They are also sometimes called “Tread Voids“.

Water can not be compressed, so these grooves provide the tires to get squished into these channels and they move out.

The tires with no grooves at all (like in the formula one cars) would not be able to roll on water, and they would just float. So in order to measure how good tires are on water, their “float speeds” are measured.

This is simply how fast a tire can go over water before it starts to float.

The more the float speed of the tire, the more resistant it is to hydroplaning (the act of floating on water).

So tires with wider grooves allow more water to pass through and they have larger float speeds.

Tread Blocks:

Stating the obvious. These are just blocks that are made with these lateral grooves (marked with yellow).

They don’t always stay in squared shape, In fact they come in all sorts of shapes, but they are still considered blocks.

On these blocks you can see sipes are well marked with the color “green”.

Sipes or Siping:

All the small lines that you see on the tread are called sipes.

As the tire rolls on wet conditions, most of the water is vacuumed out in to the grooves, but some of the water particles still get stuck underneath the ribs and the blocks of the tire.

So here sipes come in handy.

These sipes have slits in them and they suck the remaining water in them as the tire makes contact, and spray them away as the tire rolls over and is not under pressure anymore (so air can go back in them and water is expelled out).

Ribs:

Ribs is simply the opposite of grooves.

All blocks between the grooves (marked with orange) together form a Rib.

Sometimes there are no lateral grooves and so no blocks are formed. So the whole thing is called a continuous rib.

Tie Bars:

These are indicators of the tire wear.

As the tire wear, the “tread depth” becomes lesser and lesser until it reaches the height of these tire bars.

And when they do, its better to replace the tires.

(More tread depth of the tire, would mean more time for them to wear (if the material composition is also good).

Some design terms, you mostly see on All-Terrain / Off-Road Tires:

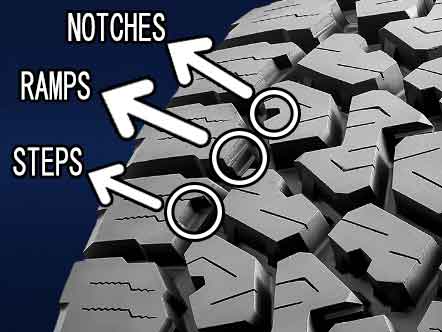

Notches:

These are chewed away parts of the blocks.

These incisions or cuts in these blocks are called notches and they provide biting edges to the ground and they are common with off road tires.

When these notches come in contact with the surface, they “try” to close up and this way they are able to grab mud/dirt/snow etc.

Although there are other terms associated with notches, like the Ramps and steps, they are all still notches.

Staggered or Serrated Edges/Shoulders:

These are edged shoulders or sides of a tire where one block has a scoop in it and the other don’t and simply makes an edge.

This allows the tire to dig in the ground and scoop out dirt/mud/debris…

A classic example of staggered shoulder can be seen by looking at the BF Goodrich KO2 tire (below).

Sidewall lugs:

(Note that the tire above also shows the sidewall lugs).

Mostly all terrain tires have sidewall designs and they are called sidewall lugs.

With bulkier sidewall lug, the tire is able to get out when aired down deep in mud.. as these sidewall lugs combined with serrated shoulder blocks act as traction scoops.

They are also helpful when the tire is pressured down and these lugs help in sidewall flexing.

Stone Ejectors:

As the name suggests, these stone ejectors, don’t let stones combined with dirt/mud/debris… to get lodged in the grooves.

They simply help in cleaning out the grooves / gaps between tread blocks.

Side Note: Lodging of mud is bad, because mud to mud contact loose grip. But snow to snow contact is good. The snow flakes interlocks with other snowflakes, or in more simpler words, snow sticks better on snow.

3 Types of Tire Designs You Should Know:

When we put all these parts together in a variety of arrangements, unique patterns that result allow the making of specialized types of tires.

Combinations of these features help tire manufacturers create products with improved car handling and other performance factors like noise, traction, and wear.

While putting together these components, treads can be developed according to different driving conditions: wet, icy, snowy, or dry, and can also be equipped for higher resistance to potential damages and greater smoothness on the road.

You will come across three types of tire treads:

Tread designs are normally classified into three basic groups, namely:

- Symmetrical

- Asymmetrical

- Directional

Symmetrical tire tread pattern:

These are the most common tire tread patterns found.

Tires with this type of pattern have continuous ribs or independent tread blocks, meaning that the outer and inner sides of the tire mirror each other.

Both halves of the tread surface are the same design.

They are also known as multi-directional as the tire can be diverted and mounted in any direction.

However, such treads aren’t suitable for high-performance uses.

Effectiveness of a symmetrical tread design?

Symmetrical tire tread pattern provides a variety of benefits, for example:

- Low rolling resistance

- Smooth driving ability

- High directional-stability

- Cost-effectiveness and comfortability

Functionality:

- This kind of tread pattern allows a person to drive smoothly and with flexible rotation.

- They also last longer and are cheaper than other choices.

- They are not quite adaptable to changing road conditions and they work best in dry conditions. So, they won’t be as effective in wet conditions as other tires.

Asymmetrical tire tread pattern:

A tire with this design consists of two different tire treads, one on the inner side and one on the outer side; such a tread pattern changes across the face of the tire. The design helps the driver achieve a smooth ride. Furthermore, these treads are covered with large tread blocks on the outer side for greater cornering stability on dry roads, and also have smaller tread blocks along the inner side; the latter help with traction and removal of water.

The outer blocks provide a larger contact area with the road surface which results in increased stability and higher traction rates. On the other hand, the inner side has high-angle sipes to soften the impact while driving, consequently leading to a quieter, more comfortable ride. Putting both of these features together, we understand how diversity helps with a car’s performance on road.

Effectiveness of an asymmetrical tread design?

The benefits of asymmetrical tire treads are:

- Excellent handling

- Good curve-stability

- Promising grip in wet conditions

- Great performance at high speed so used more in sporting vehicles.

Caution:

- These kinds of tires are more expensive than the symmetrical ones

- These tires should be installed with great care. The sidewalls are labeled as ‘Outside/Inside’ to inform the users of the right way to fix tread blocks on the rim, and thus they should be fastened in their respective places.

Directional tire tread patterns:

As suggested by the name, directional tire treads allow the tires to roll only in one direction. They have a V-shaped tread pattern, which helps move the water more efficiently from the contact patch to prevent hydroplaning at higher speed levels. This kind of pattern works best in wet conditions and is usually used for high-performance vehicles. They also perform well on snow-covered roads which is why many winter tires have directional tread patterns. Usually, arrow-based directions are given on the sidewalls of the tires bearing such treads, so that the users could be informed of how the tires should be mounted. These unidirectional tires enhance straight-line acceleration by reducing rolling resistance and providing shorter stopping distances.

Summer season directional tires perform equally well as winter tires during downpours and on wet surfaces. Winter directional tires however additionally ensure increased grip on messy roads, for example, those ridden with mud.

Effectiveness of a directional tread design?

The benefits of these tire treads:

- Good traction and braking

- High water removal for stability on wet roads and prevention of hydroplaning

- Suitable for fast driving

Caution:

- It results in a louder drive than the other tire treads

- Has low resistance to wear

- Users must follow the directional guide while fitting the tire or else it won’t function properly.

Importance of choosing the right type of Tire Tread?

The right choice of car tire tread can help:

- Improves traction.

- Improves a vehicle’s ability to steer.

- Improves stability of the tire itself.

Conclusion:

Tire treads are of three different kinds: symmetrical, asymmetrical, and directional. And all the terms we discussed together make these different kinds with their different combination.

Knowledge about all these tread types can help us understand the functionality of different tires under various conditions, for example, dry, wet, icy, or snowy.

The most commonly used ones are asymmetrical treads, and if you own a car, there’s a great chance you have that tire’s design.